Impact Research & industrial Development

Enhance the value of secondary raw materials from glass recycling, with high technological and economic added value.

Have a major impact on the amount of water wasted in water filtration, recycling and purification processes, thanks to the development of innovative materials and solutions.

Open the way to major water savings in sectors and regions now challenged in their ability to preserve this resource.

Focus on irrigation

Agriculture accounts for 70% of the water consumed by human activities. It is a strategic sector, since it must cover vital food needs now and in the future.

A seemingly abundant resource, it is becoming increasingly scarce and precious in our world of demographic and economic growth. The stakes involved in preserving water are therefore considerable and vital.

Performance of the SANDBAG® solution

The SANDBAG® solution can be used in all sand filters with a capacity of less than 400 kg of filter load, whatever the sector of application.

KOB is currently developing the performance of its SANDBAG® filtration solution with leading industrial and scientific partners in the fields of agricultural irrigation and water treatment.

Our goal: 60% minimum water savings

12 million m3

of water saved if all swimming pools in France were equipped with SANDBAG®

1 260 million m3

of water saved if all precision irrigation systems were equipped with SANDBAG® in France

224 billion m3

of water saved if all precision irrigation systems were equipped with SANDBAG® all over the World

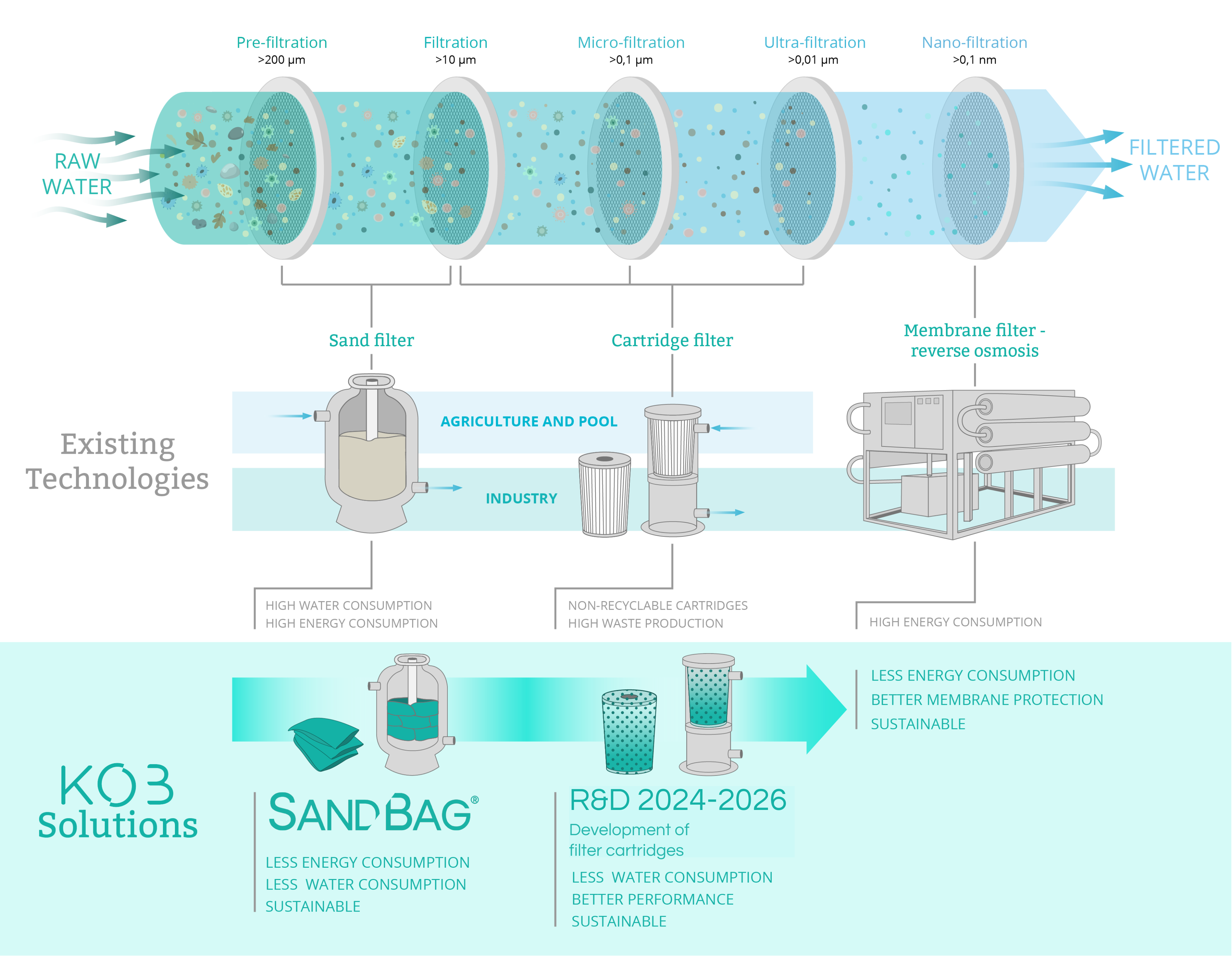

Solutions that are already outdated

Used in industry and for swimming pool filtration, filter cartridge materials are made from cellulose and/or polymers. Promoted as water-saving solutions, after just a few months of manual cleaning, these filter cartridges need to be discarded and renewed. Promues comme solutions hydroéconomes, après quelques mois de nettoyage manuel, ces cartouches de filtration doivent être jetées et renouvelées.

Major environmental and energy impacts.

In their current design and over their entire life cycle (raw material extraction, cartridge manufacture, packaging, transport, waste management), cartridge filters are undisputed champions of energy expenditure and CO2 emissions. Worse still, they become non-recyclable waste that ends up in landfill or incineration plants.

In January 2024, KOB won the AMI "Développement de la Filière Innovante de Fabrication Additive" award for its research program into the recovery of glass powders for the manufacture of sustainable, eco-responsible filtration cartridges.

The solutions of tomorrow are available today !